What We Do

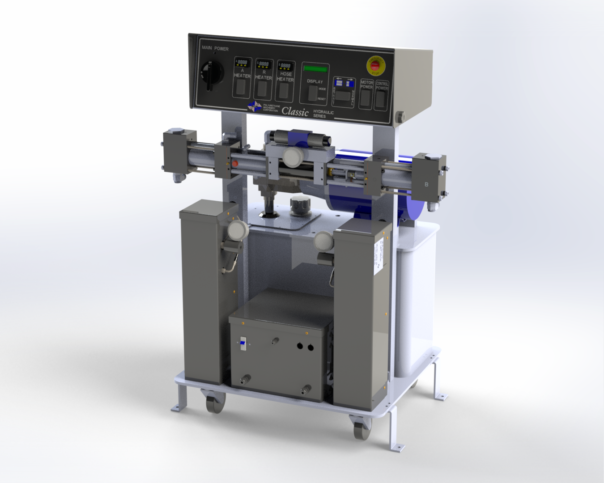

LucDesigns uses 3D CAD software (such as Solidworks) to virtually build your project. This allows you to “see” your completed product before resources are used on building prototypes. Design for Manufacture and Design for Assembly concepts are used to create assemblies that are easily manufactured and assembled. Problem areas are found and corrected on the computer, rather than on the shop floor.

Mechanical Engineering

Our foundation is rooted in mechanical engineering. Our understanding is based in stress analysis, strength of materials, thermodynamics, statics, dynamics etc. We have spent years learning how to apply these principals to real world projects. We enjoy creative thinking and a good challenge.

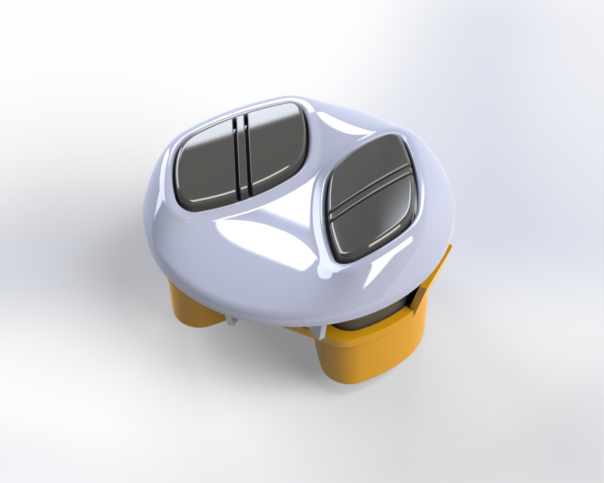

Product Design

We design elegant solutions consistent with manufacturability. Every project we work on incorporates design for manufacture and design for assembly. We have hands on experience in all facets of manufacturing and know the problem areas to avoid. Pretty and functional – yes, we can do that.

Process Improvement

We are trained in APICS and supply chain management (both internal and external). We have been involved in many ISO-9001 certifications. We understand bottlenecks, single part flow, and the benefits of integrating engineering into process control. We can assist you to push more product through your plant, and simultaneously increase quality.

Continuous Improvement

We offer packages of ongoing engineering, process control and process improvement support. We have mentored many young engineering teams in techniques that increase throughput and accuracy in engineering, fabrication, and assembly. We can review your existing processes, suggest improvements, and follow up with reviews at intervals determined by you to help hold you accountable and progress toward your optimal state.

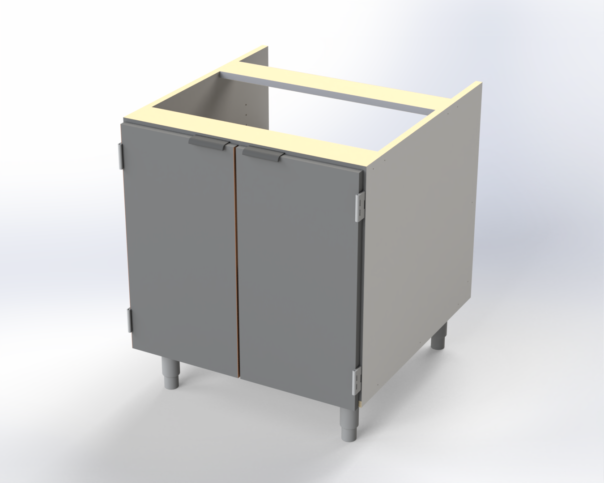

Sheet Metal Design

Are all of your engineers using the same design criteria when designing sheet metal parts? Do your engineers understand how sheet metal fabrication works – both inside CAD and on the floor? We can teach your engineering team how to streamline Solidworks so that everyone is designing with the same factors, and we can teach sheet metal concepts so that everyone understands sheet metal fabrication techniques.

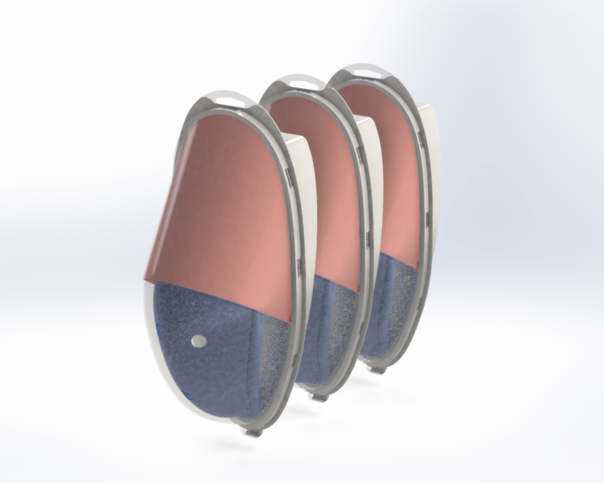

Injection Part & Mold Design

We have spent years in and around plastic injection molding plants. We have worked in mold making and machine shops. From complex surfacing, to TPE, Cams and mold motion; we have a vast knowledge of injection molded parts and injection mold design.

Display Design

We worked on the Victoria’s Secret nationwide makeup rollout, the NYX Flagship Store in CA, and the CVS makeup wall concept. We have worked on hundreds of displays that have gone through production and are in use today.

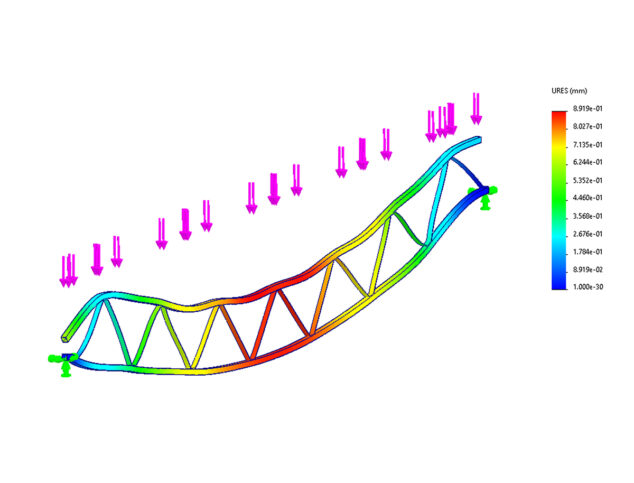

Stress Analysis

We are able to show you high stress points in any part or assembly, and suggest ways to remove or adjust the stress, making your products stronger and more resilient.

Rapid Prototype Support

Additive manufacturing, 3D printing, and rapid prototyping – they all start with LucDesigns. Did you know you will need 3D CAD data before you can make a rapid prototype or 3D model? We can help you!

MEP Code & Compliance

We have extensive knowledge of building codes such as: NEC, UL, NSF NSPC. We have designed many structures integrating plumbing, electric, lighting, and food safety.

Packaging Design

Award winning packaging design. Vac-form, Clam-Shell, RF-Seal, nesting and molds. Yes, we can do Packaging!